The company introduced advanced Japanese original FANUC machining centre and Brother machining centre in batch, combined with the traditional hand honing precision process, the accuracy of the processed products is effectively guaranteed.

Machining accuracy of connecting rod:

Parallelism of the two holes:≤0.08 /127mm Two-hole twist:≤0.12 /127mm

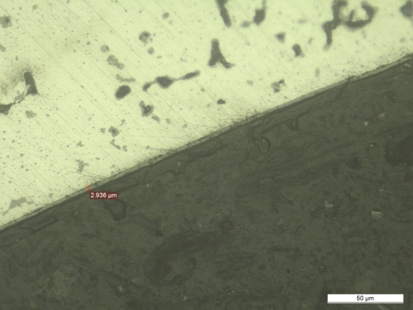

Bore size control accuracy: ≤0.0015mm Cylindricity of bore:≤0.0025mm

Surface roughness of bore:≤Ra0.3

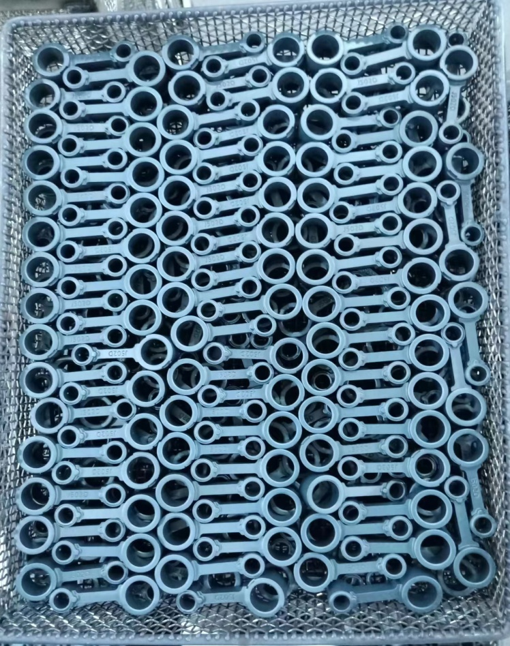

With the innovative mesh belt ST furnace bluing technology, the bluing layer is more uniform, dense and wear-resistant, and does not affect the cylindricity and roughness of the original bore, and the hardness of the bluing layer reaches HRB55-65.

Adopting advanced and efficient processing technology and internally developed new valve plate processing technology, high-precision compressor valve plates are produced to effectively improve compressor performance.

The valve plate processed with the new patented technology, the flatness of the valve seat surface and the valve piece mounting surface is controlled within 0.002mm, and the height difference between the two surfaces is controlled within 0.01mm (95% of the products have a height difference within 0.005mm).

The products are cleaned using both ultrasonic cleaning machines and high pressure spraying to effectively ensure the cleanliness of the product surface.

The product is packed to prevent rust, using a dual process of vapour phase rustproof paper and evacuation, which can effectively prevent rust for more than six months without removing the packaging.